Track roller guidance systems

Features

Track roller guidance systems are available with a hollow section carriage, compact carriage, open carriage, non-locating bearing carriage or bogie carriage.

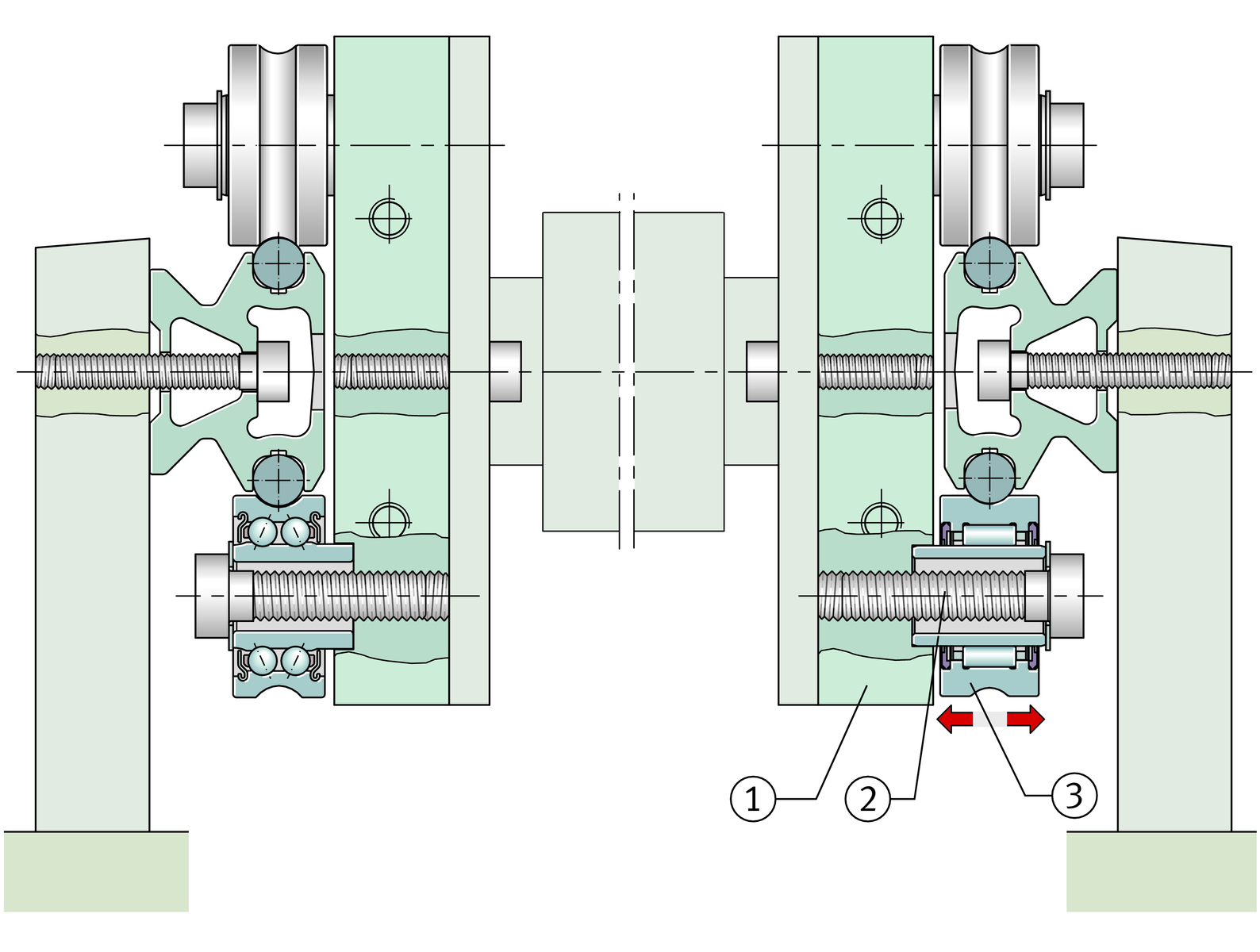

Track roller guidance system with non-locating bearing carriage

Non-locating bearing carriages LFLL..-SF are robust, ready-to-fit linear guidance systems that are used exclusively in locating or non-locating bearing applications with two parallel guideway systems. The track rollers can be axially displaced. In this way, it is possible to compensate inaccuracies of ±1 mm in relation to the spacing of the guideways.

A carriage comprises a carriage plate made from anodised aluminium, four screws and four non-locating bearing track rollers, ➤ Figure. The track rollers are already fitted.

Non-locating bearing carriage

Preload and clearance

The carriages run clearance-free on all INA guideways and can be combined with all guideways of the relevant size, but not with the curved guideway elements LFSR. Due to the highly accurate guideways, it is not necessary to set the clearance.

Sealing and lubrication

The track rollers have gap seals on both sides, are greased for life and are therefore maintenance-free.

The contact zone between the raceways and track rollers must be lubricated via the shaft.

Corrosion-resistant design

All steel parts, the inner and outer rings of the track rollers and the screws, washers and nuts are made from corrosion-resistant steel.

The rolling elements are protected against corrosion by the grease.

Corrosion-resistant designs have the suffix RB (available by agreement only).

ACHTUNG

Non-locating bearing carriages must never be used on their own but only ever in combination with locating bearing carriages.

The track rollers can support loads in a radial direction only.