Accessories

Damping carriages

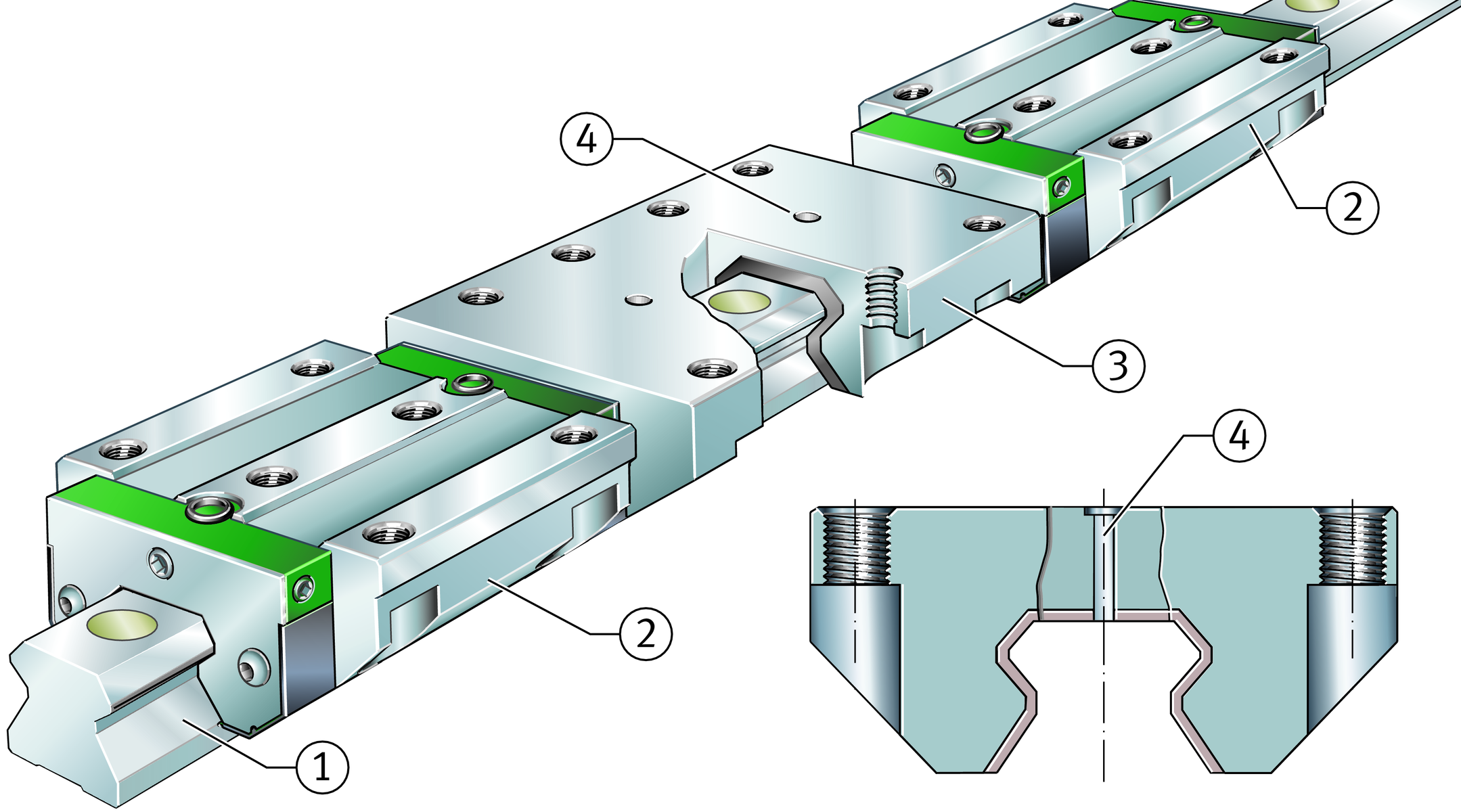

Damping carriages RUDS..-D reduce vibrations acting on the guidance system. They improve operating results, extend the service life of the tools under vibration and increase the crash safety of the guidance system.

The damping carriage is arranged on the guideway in addition to the carriages and is screw mounted to the adjacent construction, ➤ Figure and ➤ Figure.

The additional damping element does not influence the special characteristics of the rolling element guidance system, such as low displacement resistance and high running accuracy.

The damping carriage is available for RUE..-E. It must always be ordered together with a monorail guidance system.

In addition to the damping carriage RUDS, Schaeffler also offers a fully hydrostatic guidance system HLE45.

Damping carriage

Linear recirculating roller bearing and guideway assembly with damping carriage

Damping by oil film

The carriage damps vibrations acting on the guidance system by means of an oil film (squeeze film effect) between the damping carriage and the guideway, ➤ Figure. The damping effect increases with the size of the damping surface and the width of the gap. During operation, the guideway and damping carriage are not in contact with each other. The supply of oil by the oil drop method must be ensured. The oil reaches the damping surface via lubrication holes in the back of the element.

Frequency – with and without damping carriage

ACHTUNG

Damping carriages do not have locating faces. The elements should never be laterally abutted.

The damping carriage must be centred on the guideway during mounting, in order that the gap between the guideway and damping carriage is of uniform size on all sides.

Counterbores in the guideways should only be closed off using brass closing plugs KA..-M. The covering strips ADB and ADK must not be used.